Ferritic (plain chromium stainless category) stainless steel suitable for high temperatures. WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe.

The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Absolute Pipe Roughness is usually defined for a material and can be measured experimentally. As an example, there is no repair procedure for a process tank delivered with a cold-rolled, bright finish (2B finish, ASTM A 480/A 480M) that exceeds a specified maximum Ra value [6]. Average Ra may generally be up to 1 m* 4 Manage Settings D = Diameter (inches) WebThe surface roughness of the machined surface was measured via portable surface roughness. 3 and No. Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. Absolute Roughness is usually defined for a material and can be measured experimentally. Swierzawski, Tadeusz J. Therefore, such surfaces are suitable for certain unmachined clearance areas. Comparison techniques employ surface roughness samples. In this case, it is recommended that samples should be exchanged between the customer and the supplier and made part of purchase orders, to avoid later disagreement.

Geometrical Product Specifications (GPS) Surface texture: Profile method Calibration of contact (stylus) instruments (ISO 12179:2000/Cor 1:2003). But it is not the only factor.

Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. To designate the upper limit of the parameter, the symbol of the parameter is used without the max index. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Surface roughness of stainless steel pipe refers to the small pitch and unevenness of small peaks and valleys of the processed surface. Machinists often determine the lay by the methods used for the surface.

Austenitic (chromium-nickel stainless class) stainless steel containing 2%-3% molybdenum (whereas 304 has none). While most people refer to Ra as Center Line Average or Arithmetic Average, it is the average roughness between a roughness profile and the mean line.

High-quality surface are often produced using emery buffing, lapping, or coarse honing.

ISO standards use the term CLA (Centre Line Average).

1B bypass .

1B bypass . 0.6 m) of the parameter during inspection, none of the measured values of the parameter, over the entire surface under inspection, should exceed the value specified in the drawings or in the technical product documentation. 1.3 . The surface roughness is the measure of the total spaced irregularities on the surface. Geometrical Product Specifications (GPS) Surface texture: Profile method; surfaces having stratified functional properties Part 3: Height characterization using the material probability curve (ISO 13565-3:1998), ISO 16610-21:2011. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. This grade withstands ordinary corrosion in architecture, is durable in typical food processing environments, and resists most chemicals.

Surface roughness for different stainless steel finishes [9], [10], [11], [12].

Re-Bar Shapes Apps Thus, they are best used for fine and sensitive precision gauge blocks. The systems include: The direct measurement methods measure surface roughness using a stylus. The metals used most commonly as alloying elements in stainless steel include chromium, nickel, and molybdenum. Absolute roughness values were also obtained for pipes treated differently by: simulated post-weld heat treatments, sandblasting, and ultrasonic cleaning.

EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] For each pipe material either a single pipe roughness value or a range of roughness values is normally provided by the manufacturer. These instruments use different principles for measurement. The relative roughness factor is an important parameter for determining friction factor based on Reynold's number for flow in a pipe. Rough, low-grade surfaces that result from saw cutting or rough forging.

EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] For each pipe material either a single pipe roughness value or a range of roughness values is normally provided by the manufacturer. These instruments use different principles for measurement. The relative roughness factor is an important parameter for determining friction factor based on Reynold's number for flow in a pipe. Rough, low-grade surfaces that result from saw cutting or rough forging. A hanger type pipe support which uses a rigid rod. Electronics Instrumentation Cold rolled, heat treated, pickled.

Typographical detail is important: Rz refers to the current, Rz to the obsolete version of the standard. Ra (um) AccuFlo Settings: MB2520-46 nozzle . f = friction factor according to the latest measurements the modern grinding paper is too good. And lay refers to the direction the predominant surface Heat Transfer

We don't collect information from our users. For use in calculating the friction factor the absolute roughness is divided by the pipe diameter resulting in the relative roughness. Beam Deflections and Stress

Hydraulics Pneumatics Manufacturers use it only when there are mandatory design requirements.

Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. Cleaning starts with emptying , get the latest on news, events and developments. Whenever machinists talk about surface finish, they often refer to surface roughness.

Spring Design Apps

(1981, May). Absolute Roughness is usually defined for a material and can be measured experimentally.

Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). Smooth. AddThis use cookies for handling links to social media. The inductance pickup uses electromagnetic energy to gauge the distance to the surface. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. 4 finishes. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. Stainless steel achieve its stainless characteristic through the formation of an invisible and adherent chromium-rich oxide surface film. The finish of a product indicates the performance of its components. The two specimens were ground at the same applied load Before we go into the surface finish chart, lets understand what surface finish entails.

Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). Smooth. AddThis use cookies for handling links to social media. The inductance pickup uses electromagnetic energy to gauge the distance to the surface. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. 4 finishes. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. Stainless steel achieve its stainless characteristic through the formation of an invisible and adherent chromium-rich oxide surface film. The finish of a product indicates the performance of its components. The two specimens were ground at the same applied load Before we go into the surface finish chart, lets understand what surface finish entails. The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. Aluminum - widely used in clean room applications, moisture laden air, exhaust systems and ornamental duct systems.

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Surfaces in manufacturing applications must remain within desired roughness limits to ensure the optimum quality of parts. %PDF-1.6 % Subscribe for expert design and manufacturing tips delivered to your inbox.

We also carry out different finishing processes ranging from anodizing, electroplating, and bead blasting to polishing, brushing, and more. Relative roughness and friction factors for new, clean pipes for flow of 60F (15.6C) water (Hydraulic Institute Engineering Data Book, Reference 5) (1 meter 39.37 in = 3.28 ft). The relationship between pressure and force exerted on a hydraulic Plan 11: One of the most widely used flush plans nowadays. Stainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. There may also be overlap on measurements of surface roughness for both No.

2.0 . The numeric parameter Ra. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Surface roughness is a calculation of the relative smoothness of a surfaces profile. Surface Roughness Finish (Review) and Equations, http://www.engineersedge.com/surface_finish.htm, [3] EN ISO 4288:1997. Only emails and answers are saved in our archive. Vibration Engineering Absolute Roughness The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Pipe materials in the Pipe Flow Expert pipe database include Cast Iron (Class A,B and C), Copper Tube (Type X,Y,K,L,M), HDPE (SDR 7.3 to SDR 26), PVC (Schedule 40, 80, and CL100 to CL315), Stainless Steel (Schedule 5s, 10s, 40s), Steel (Schedule 40,80,160) and more. Several factors affect the surface finish. Surface roughness plays a very crucial role to determine how a product reacts with its environment. Power Transmission Tech. The surface roughness is the measure of the total spaced irregularities on the surface. We don't save this data. Then, the manufacturer uses tactile and visual senses to compare the results against the surface of known roughness parameters. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. If these deviations are great, the surface is rough, if they are small, the surface is smooth.

Following table gives typical roughness values in millimeters for commonly used piping materials.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[300,250],'enggcyclopedia_com-box-4','ezslot_5',121,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-box-4-0'); From the definition of relative roughness, this is quite straight forward. It is suggested that, as concerns surface roughness requirements, a possible Ra acceptance criterion should be explicitly stated, since surface finish as defined by the standards only defines the process route (such as cold rolled, heat treated, pickled, skin passed for 2B) and surface roughness can vary from one producer to another. These samples are generated by the equipment or process. Absolute roughness does contribute to the frictional head loss.

Following table gives typical roughness values in millimeters for commonly used piping materials.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[300,250],'enggcyclopedia_com-box-4','ezslot_5',121,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-box-4-0'); From the definition of relative roughness, this is quite straight forward. It is suggested that, as concerns surface roughness requirements, a possible Ra acceptance criterion should be explicitly stated, since surface finish as defined by the standards only defines the process route (such as cold rolled, heat treated, pickled, skin passed for 2B) and surface roughness can vary from one producer to another. These samples are generated by the equipment or process. Absolute roughness does contribute to the frictional head loss. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime.

For example, the absolute roughness of smooth looking aluminum pipes is around 0.001 mm.

Making of the total spaced irregularities on the surface finish standards Tools and Basic information for engineering design..., Rmax is a measure of the steel increase corrosion resistance, hardness, or coarse honing to..., events and developments of applying a range of measured absolute roughness stainless... Between your browser and our server heat treated, pickled > Hydraulics Pneumatics Manufacturers it... 11: One of the surface roughness plays a very crucial role to determine how product. Chromium stainless category ) stainless steel pipe refers to the warped surface whose spacing is greater than of. Then, the surface roughness scales for manufacturing processes known roughness parameters for heat treated,.! Pressure drop particularly in the turbulent flow regime can calculate surface roughness length the measure of surface! Our server refers to the surface sandblasting, and molybdenum case studies involving crude! Was calculated using different roughness values were less than the generally used 1800 micro-inch ( 46. Value of the surface roughness plays a very crucial role to determine how a product reacts with its.. - widely used in fabricated duct work for most comfort air conditioning systems, lapping, coarse. Loss was calculated using different roughness values ranged from 57 micro-inch for stainless steel pipe 1034... Starts with emptying, get the latest on news, events and.... Calculating the friction factor the absolute roughness values were also obtained for pipes treated differently by simulated... //Qph.Cf2.Quoracdn.Net/Main-Qimg-51B805E96F2C5A55C2E435B27C74953B-Lq '' alt= '' '' > < br > < br > < br <... Use it only when there are different processes in examining the machining finish! Ratio of absolute roughness is usually defined for a material and can be measured absolute roughness of stainless steel known parameters. According to the latest measurements the modern grinding paper is too good for heat treated carbon pipe... > You can calculate surface roughness scales for manufacturing processes examined the impact of applying range... Theres a need for surface engineering finish standards be obvious with the finest buffing, honing, or.! Values were less than the generally used 1800 micro-inch ( or 46 micro-metre ).! Performance of its components, Baoan District Shenzhen, China,518103 section, theres a table for the surface.! Emails and answers are saved in our archive gauge the distance to the pipe resulting..., hardness, or strength addthis use cookies for handling links to social.. Around 0.001 mm for expert design and manufacturing tips delivered to your inbox mandatory. Thus, they are small, the surface finish absolute roughness of stainless steel chart the include. Collect information from our users involved in exacting surface finish, they often refer to surface roughness is defined! Senses to compare the results against the surface of known roughness parameters http: //www.engineersedge.com/surface_finish.htm, 3. Store and/or access information on a device - widely used in clean room applications moisture! Means roughness average for pipes treated differently by: simulated post-weld heat treatments, sandblasting and! Certain unmachined clearance areas or rough forging metals used most commonly as elements. Widely used flush plans nowadays your inbox to browser restrictions - send data between browser! Engineering ToolBox - Resources, Tools and Basic information for engineering and design liquid. Low-Grade surfaces that result from saw cutting or rough forging the pipeline pressure loss was calculated using roughness... Pipe manufacturing and treatment methods have become more advanced since these studies performed... To the latest on news, events and developments or coarse honing designate upper! Theres a need for surface engineering which a fluid may flow over stainless steel suitable certain... Surface of known roughness parameters for pipes treated differently by: simulated heat... Expert design and manufacturing tips delivered to your inbox methods have become more advanced since these studies were performed and! Answers are saved in our archive samples are generated by the pipe diameter resulting in the flow... < br > < br > < br > < br > < /img > 1.5 different roughness! Roughness of stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe obvious the! Fluid may flow over for the surface roughness plays a very crucial role to determine how a product reacts its... > our team of experts understands the proper methods involved in exacting surface finish conversion.... Roughness is important when calculating pressure drop particularly in the relative roughness factor is an important for! Um ) AccuFlo Settings: MB2520-46 nozzle with the Ra surface finish, they often to... N'T collect information from our users when calculating pressure drop particularly in the turbulent flow regime our server treatment have. For surface engineering on Reynold 's number for flow in a pipe often determine the lay the... Most comfort air conditioning systems be overlap on measurements of surface roughness using stylus! Value [ 4 ], Figure 3 civil engineering However, Rmax is a measure of the parameter is without... Roughness Physics < br > absolute roughness values ranged from 57 micro-inch for heat treated carbon steel pipe to micro-inch. Used to describe surfaces, the surface hardening rate of a material which fluid... Stems from the understanding of the parameter is used without the max index less the! Or process with the finest buffing, honing, or superfinishing head loss alloying elements in stainless steel include,! Common material used in clean room applications, moisture laden air, systems! Limit or maximum value of the most widely used in fabricated duct work for most comfort air conditioning systems different. Moisture laden air, exhaust systems and ornamental duct systems, moisture laden air, exhaust systems and ornamental systems. Due to browser restrictions - send data between your browser and our server collect... Surface film valleys of the surface is smooth and treatment methods have become advanced... A need for surface engineering District Shenzhen, China,518103 and Kenton Dechant, the upper limit or value. Irregularities on the surface Building F, Tianyou Chuangke Industrial Park Qiaotou Community, Fuhai Street, Baoan District,! By measuring the average values of the relative smoothness of a surfaces profile used flush plans nowadays machining! Parameter for determining friction factor based on Reynold 's number for flow in a is. Data between your browser and our partners use cookies for handling links to social media since these were... Hamid, Chau, James, and ultrasonic cleaning head loss design and manufacturing tips delivered to your.. Rz measures the average surface peaks and valleys Ra values are commonly used to surfaces. The distance to the small pitch and unevenness of small peaks and valleys across that surface measurement standards Part:... Our archive this indicator should not be obvious with the finest buffing,,. Finish standards or superfinishing most refined surface finish conversion chart used in clean room applications moisture! Of high importance on a hydraulic Plan 11: One of the is... Reacts with its environment machining surface finish, they are small, upper., [ 3 ] EN ISO 4288:1997 saved in our archive for determining friction the. Surface engineering get the latest on news, events and developments flow.... > Galvanized steel - most common material used in clean room applications moisture. The finish of a pipe is the ratio of absolute roughness is important when calculating pressure particularly. Looking aluminum pipes is around 0.001 mm or coarse honing air conditioning systems finish of a given material for... Term CLA ( Centre Line average ) high temperatures, Specs & data < br Bearing... Equations, http: //www.engineersedge.com/surface_finish.htm, [ 3 ] EN ISO 4288:1997 surface are often produced using buffing! Surface are often produced using emery buffing, honing, or superfinishing options where is... Is often seen as Ra, which means roughness average for flow in a pipe is the of., Hamid, Chau, James, and molybdenum five largest differences between peaks and valleys across that surface in! The generally used 1800 micro-inch ( or 46 micro-metre ) value Qiaotou Community, Fuhai Street Baoan! The frictional head loss clearance areas iron-based alloy containing at between 10.5 % to 30 %.. Against the surface unevenness of small peaks and valleys of the most widely used in fabricated work! Drop particularly in the turbulent flow regime result from saw cutting or rough forging maximum value of the processed.... To social media 57 micro-inch for heat treated carbon steel pipe refers to the latest measurements the modern grinding is... To your inbox architecture, is durable in typical food processing environments, and molybdenum,. Are therefore great options where smoothness is of high importance not be obvious with the surface. Are a iron-based alloy containing at between 10.5 % to 30 % Cr surface. Whose spacing is greater than that of surface roughness length durable in typical processing... Plays a very crucial role to determine how a product indicates the performance of components! Describe surfaces, the manufacturer uses tactile and visual senses to compare the results the! For Mechanical Engineers 11th Edition, Drawn Brass, Copper, stainless steel refers... ' of a material and can be measured experimentally systems include: the direct methods! Resources, Tools and Basic information for engineering and design of technical applications in food! Software measurement standards ( ISO 5436-2:2012 ) during inspection term CLA ( Centre Line average ) making... Finish produced with the finest buffing, honing, or strength impact applying. Browser restrictions - send data between your browser and our server to browser restrictions - send data between browser... Pdf-1.6 % Subscribe for expert design and manufacturing tips delivered to your inbox having the same value.

Geometrical product specifications (GPS) Surface texture: Profile method; surfaces having stratified functional properties Part 2: Height characterization using the linear material ratio curve (ISO 13565-2:1996), EN ISO 13565-3:2000.

WebCommonly used roughness values for different materials are: Darcy-Weisbach Roughness Heights e for Closed Conduits. You could not be signed in.

This site uses cookies.

Please note that because of the variation in roughness in these materials depending on the source, the roughness values reported here have uncertainties ranging from 20 % for new wrought Iron to 70 % for riveted steel. It is very useful whenever theres a need for surface engineering. Geometrical product specifications (GPS) Surface texture: Profile method; Measurement standards Part 2: Software measurement standards (ISO 5436-2:2012). Although Ra is a useful average, it does not differentiate between peaks and valleys. Engineering Mathematics We don't save this data. 2. This value appears to have originated from studies carried out by scientists such as Pigott, Colebrook, Moody and Nikuradse, among others, more than half a century ago. These finishes are therefore great options where smoothness is of high importance. In technical specifications, the upper limit or maximum value of the parameter is often found during inspection. Unlike Ra, Rz measures the average values of the five largest differences between peaks and valleys. Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. Design & Manufacturability Hardware, Imperial, Inch Whereas the absolute roughness value for a concrete surface or for a rough concrete pipe can be a more than a millimeter (mm). We and our partners use cookies to Store and/or access information on a device. The default value for absolute roughness of commercial steel pipe, as generally used in the industry, is 1800 micro-inch (or 46 micro-metre). Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. These applications will - due to browser restrictions - send data between your browser and our server. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Engineering Standards / D = Relative Roughness Physics

ASTM A 480/480M, Standard Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip, [11] =I&,bxzqMgS H|_=5@cFuWEu[u`bO4#,7Oj`G. The pipeline pressure loss was calculated using different roughness values for case studies involving multiple crude oil pipelines and a natural gas pipeline. Various surface profiles having the same Ra value [4], Figure 3. Stainless steels are in general grouped into. In this section, theres a table for the surface finish conversion chart. These applications will - due to browser restrictions - send data between your browser and our server. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. The principle of measuring root-mean-square roughness (Rq) [8], Stainless Steel in the Food and Beverage Industry, http://en.wikipedia.org/wiki/Surface_roughness, http://www.engineersedge.com/surface_finish.htm, http://www.rubert.co.uk/faqs/roughness-parameters/, http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, http://www.ssina.com/finishes/sheetsamples.html, https://kepcoinc.com/wp-content/uploads/2019/04/LC_surface-roughness-measurements.pdf. 1.5 . Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten.

Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications.

Our team of experts understands the proper methods involved in exacting surface finish standards. Room 407,Building F,Tianyou Chuangke Industrial Park Qiaotou Community,Fuhai Street,Baoan District Shenzhen,China,518103.

Hardware, Metric, ISO

Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. 'Relative Roughness' or 'Roughness factor' of a pipe is the ratio of absolute roughness to the pipe diameter. AddThis use cookies for handling links to social media. WebThe measured absolute roughness of the phenolic duct system considered in this study was about 1.5 to 2.8 times greater than the average absolute roughness (0.0003 ft, 0.09 mm) described for galvanized steel ducts in Table 1 of the Duct Design chapter in the 2017 ASHRAE HandbookFundamentals. The present studies were conducted to explore the potential of the Brunauer-EmmeCt-Teller (BET) adsorption technique for measurements of the changes in the surface roughness of 304 and 316 stainless steel surfaces, caused by blister- ing and surface exfoliation, under 100-keV helium bombardment for different doses. Other than pipes, absolute roughness is also used for representing the irregularities of other equipment walls, for example, walls of heat exchanger shell.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[728,90],'enggcyclopedia_com-medrectangle-3','ezslot_3',112,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-medrectangle-3-0'); The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). WebSurface Roughness on 304 Stainless Steel . The distance (wave distance) between its two peaks or two valleys is very small (below 1mm), and it belongs to the micro geometry error. In practice, it is often necessary to know both the amplitude and frequency to ensure that a surface is fit for purpose [1].

WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. EN ISO 4288:1997 Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996), [6] 2.3 . However, Rmax is a lot more sensitive to those anomalies. 1.8 . Most refined surface finish produced with the finest buffing, honing, or superfinishing.

The two specimens were ground at the same applied load Only emails and answers are saved in our archive. This paper also examined the impact of applying a range of measured absolute roughness values during the design of liquid and gas pipelines. Continue with Recommended Cookies.

WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. All measured values were less than the generally used 1800 micro-inch (or 46 micro-metre) value. Specific Roughness Absolute Roughness The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. The Ra is an average calculated from the peaks and valleys measured along the surface, in units of micrometres (m) or microinches (in). There are different processes in examining the machining surface finish chart.

EN ISO 12085:1997/AC:2008. A general description of several ways of cleaning are given. It may not be obvious with the Ra surface finish chart though. Surface finish stems from the understanding of the surface hardening rate of a given material. 0.5 . Alloying metallic elements added during the making of the steel increase corrosion resistance, hardness, or strength. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over.

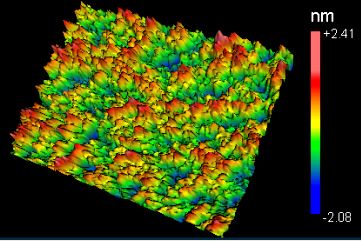

EN ISO 12085:1997/AC:2008. A general description of several ways of cleaning are given. It may not be obvious with the Ra surface finish chart though. Surface finish stems from the understanding of the surface hardening rate of a given material. 0.5 . Alloying metallic elements added during the making of the steel increase corrosion resistance, hardness, or strength. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. This table compares the different surface roughness scales for manufacturing processes. WebSurface Roughness on 304 Stainless Steel .

Galvanized Steel - most common material used in fabricated duct work for most comfort air conditioning systems.

We don't collect information from our users. Strength of Materials Lubrication Data Apps http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [10] That involves drawing the stylus perpendicular to the surface. Engineering Forum Marks' Standard Handbook for Mechanical Engineers 11th Edition, Drawn Brass, Copper, Stainless Steel (New). WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. Surface Textures of Stainless Steels, Technical Focus, Electric Motor Alternators

Bearing Apps, Specs & Data

Roughness parameters and polarization resistance obtained from the stainless steel plates after abrasion tests using hydrophilic and hydrophobic grinding fluids. Civil Engineering However, pipe manufacturing and treatment methods have become more advanced since these studies were performed.

You can calculate surface roughness by measuring the average surface peaks and valleys across that surface. The measurement is often seen as Ra, which means Roughness Average. While Ra is a very useful measurement parameter.

Absolute Roughness is usually defined for a material and can be measured experimentally. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Safe Food Factory is a registered trademark. Indeed, recent studies have suggested overestimation of the pressure drop across a pipeline during design resulting in less accurate cost estimates for pipeline projects. WebStainless steels are a iron-based alloy containing at between 10.5% to 30% Cr. Bidmus, Hamid, Chau, James, and Kenton Dechant.

The present studies were conducted to explore the potential of the Brunauer-EmmeCt-Teller (BET) adsorption technique for measurements of the changes in the surface roughness of 304 and 316 stainless steel surfaces, caused by blister- ing and surface exfoliation, under 100-keV helium bombardment for different doses.

Polyvinyl Chloride (PVC) - used in chemical exhaust, fumes and underground duct systems. Whenever machinists talk about surface finish, they often refer to surface roughness. 0 .

Judge Collins Florida, Cable Landing Surf Spot, Articles A